Table of Contents

1. Objective

The workability of fresh concrete is a composite property, which includes the diverse requirements of stability, mobility, compactability, placeability and finishability. There are different methods for measuring the workability. Each of them measures only a particular aspect of it and there is really no unique test, which measures workability of concrete in its totality. The Vee Bee Consistometer Test indicates the workability of fresh concrete.

This test gives an indication of the mobility and to some extent of the compactibility of freshly mixed concrete. The test measures the relative effort required to change a mass of concrete from one definite shape to another (i.e., from conical to cylindrical) by means of vibration. The amount of effort (called remoulding effort) is taken as the time in seconds, required to complete the change.

The results of this test are of value when studying the mobility of the masses of concrete made with varying amounts of water, cement and with various types of grading of aggregate. The time required for complete remoulding in seconds is considered as a measure of workability and is expressed as the number of Vee-Bee seconds. The method is suitable for dry concrete. For concrete of slump in excess of 50mm, the remoulding is so quick that the time cannot be measured.

2. Apparatus Required

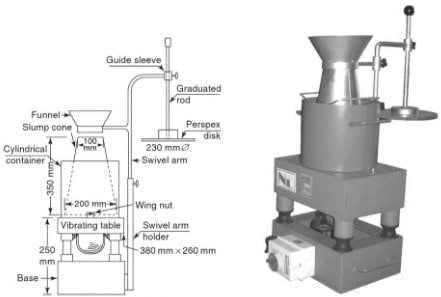

| Fig. 1: Vee-Bee Consistometer a) A vibrator table resting upon elastic supports b) A metal pot c) A sheet metal cone, open at both ends d) A standard iron rod, Tamper (20 mm in diameter and 500 mm length) |

| Fig. 2: Balance A balance should be able to weigh up to 1 g accuracy. |

3. Reference

IS 1199: 1959 Methods of Sampling and Analysis of Concrete (Eleventh revision). Reaffirmed- Dec 2013.

4. Procedure

- Slump test as described in “IS 1199:1959 Specifications for Concrete Slump Test Apparatus (Fourth revision). Reaffirmed- Dec 2013”. is performed, placing the slump cone inside the sheet metal cylindrical pot of the consistometer.

- The glass disc attached to the swivel arm shall be moved and placed just on the top of the slump cone in the pot and before the cone is lifted up, the position of the concrete cone shall be noted by adjusting the glass disc attached to the swivel arm. The cone shall then be lifted up and the slump noted on the graduated rod by lowering the glass disc on top of the concrete cone. The electrical vibrator shall then be switched on and the concrete shall be allowed to spread out in the pot.

- The vibration is continued till such time as the conical shape of the concrete disappears and the concrete assumes a cylindrical shape. This can be judged by observing the glass disc from the top for the disappearance of transparency.

- Immediately when the concrete fully assumes a cylindrical shape, the stopwatch is switched off. The time required for the shape of concrete to change from slump cone shape to cylindrical shape in seconds is known as Vee Bee Degree.

- This method is very suitable for very dry concrete whose slump value cannot be measured by the Slump Test, but the vibration is too vigorous for concrete with a slump greater than about 50 mm.

5. Observation And Recording

The time required for the shape of concrete to change from slump cone shape to cylindrical shape in seconds is known as Vee Bee Degree

6. Result

The Vee Bee Degree of concrete ………….. second(s) indicate Low/ Medium/ High Degree of workability

| Code | Description of Book | Download Link |

|---|---|---|

| IS 456:2000 | Plain and Reinforced Concrete - Code of Practice | Download |

| IS 383:1970 | Specifications for fine & coarse aggregate from natural sources for concrete | Download |

| IS 2386 (Part I) 1963 | Methods of Test for Aggregates for Concrete, Part I: Particle Size and Shape | Download |

| IS 2386 (Part II) 1963 | Methods of test for aggregates for concrete, Part II: Estimation of deleterious materials and organic impurities | Download |

| IS 2386 (Part III) 1963 | Methods of test for aggregates for concrete, Part 3: Specific gravity, density, voids, absorption and bulking | Download |

| IS 2386 (Part IV) 1963 | Methods of test for aggregates for concrete, Part 4: Mechanical properties | Download |

| IS 2386 (Part V) 1963 | Methods of Test for Aggregates for Concrete, Part V: Soundness | Download |

| IS 2386 (Part VI) 1963 | Methods of test for aggregates for concrete, Part 6: Measuring mortar making properties of fine aggregates | Download |

| IS 2386 (Part VII) 1963 | Methods of Test for Aggregates for Concrete, Part VII: Alkali Aggregate Reactivity | Download |

| IS 2386 (Part VIII) 1963 | Methods of Test for Aggregates for Concrete, Part VIII: Petrographic Examination | Download |

| IS 2430-1986 | Methods for Sampling of Aggregates for Concrete | Download |

| IS 4082-1996 | Recommendations on stacking and storage of construction materials and components at site | Download |

| IS 2116-1980 | Sand for masonry mortars - Specifications | Download |

| IS 2250-1981 | Code of Practice for Preparation and Use of Masonry Mortars | Download |

| IS 269-1989 | Specification for Ordinary Portland Cement, 33 Grade | Download |

| IS 8112-2013 | Specification for 43 grade ordinary Portland cement | Download |

| IS 12269-1987 | Specification for 53 grade ordinary Portland cement (BI-LINGUAL) | Download |

| IS 455-1989 | Portland Slag Cement - Specification | Download |

| IS 1489-1991 (Part-I) | Specification for Portland Pozzolana cement, Part 1: Flyash based | Download |

| IS 1489-1991 (Part-II) | Specification for Portland-Pozzolana cement, Part 2: calcined clay based | Download |

| IS 6909-1990 | Specification for supersulphated cement | Download |

| IS 8041-1990 | Specification for rapid hardening Portland cement | Download |

| IS 12330-1988 | Specification for sulfate resisting Portland cement | Download |

| IS 6452 (B)-1989 | High alumina cement for structural use(BI-LINGUAL) | Download |

| IS 4031-1996 (Part-I) | Methods of physical tests for hydraulic cement, Part 1: Determination of fineness by dry sieving | Download |

| IS 4031-1999 (Part-II) | Methods of physical tests for hydraulic cement, Part 2: Determination of fineness by specific surface by Blaine air permeability method | Download |

| IS 4031-1988 (Part-III) | Methods of physical tests for hydraulic cement, Part 3: Determination of soundness | Download |

| IS 4031-1988 (Part-IV) | Methods of physical tests for hydraulic cement, Part 4: Determination of consistency of standard cement paste | Download |

| IS 4031-1988 (Part-V) | Methods of physical tests for hydraulic cement, Part 5: Determination of initial and final setting times | Download |

| IS 4031-1996 (Part-VI) | Methods of physical tests for hydraulic cement, Part 6: Determination of compressive strength of hydraulic cement (other than masonry cement) | Download |

| IS 4031-1988 (Part-VII) | Methods of physical tests for hydraulic cement, Part 7: Determination of compressive strength of masonry cement | Download |

| IS 4031-1988 (Part-VIII) | Methods of physical tests for hydraulic cement, Part 8: Determination of transverse and compressive strength of plastic mortar using prism | Download |

| IS 4031-1988 (Part-IX) | Methods of physical tests for hydraulic cement, Part 9: Determination of heat of hydration | Download |

| IS 4031-1988 (Part-X) | Methods of physical tests for hydraulic cement, Part 10: Determination of drying shrinkage | Download |

| IS 4031-1988 (Part-XI) | Methods of physical tests for hydraulic cement, Part 11: Determination of density | Download |

I hope this article will help you. You may also want to see my other post from my Blog. If I have missed anything here, please let me know about that in the comment below this post.

Share it with your friends.

Happy Learning.

If you liked this article, then please help me to share this article with your friends through Facebook, Twitter, WhatsApp or Instagram. You can also find us on Facebook, Twitter, Instagram, Telegram Channel, YouTube Channel, and Pinterest. Also, Subscribe to our mailing list to get a new post update from us. And, do me a favour, if you find this post helpful, rate a 5 star below-